Parafusos de cabeça panela de precisão ultra-micro, aço inoxidável M0.5-M3

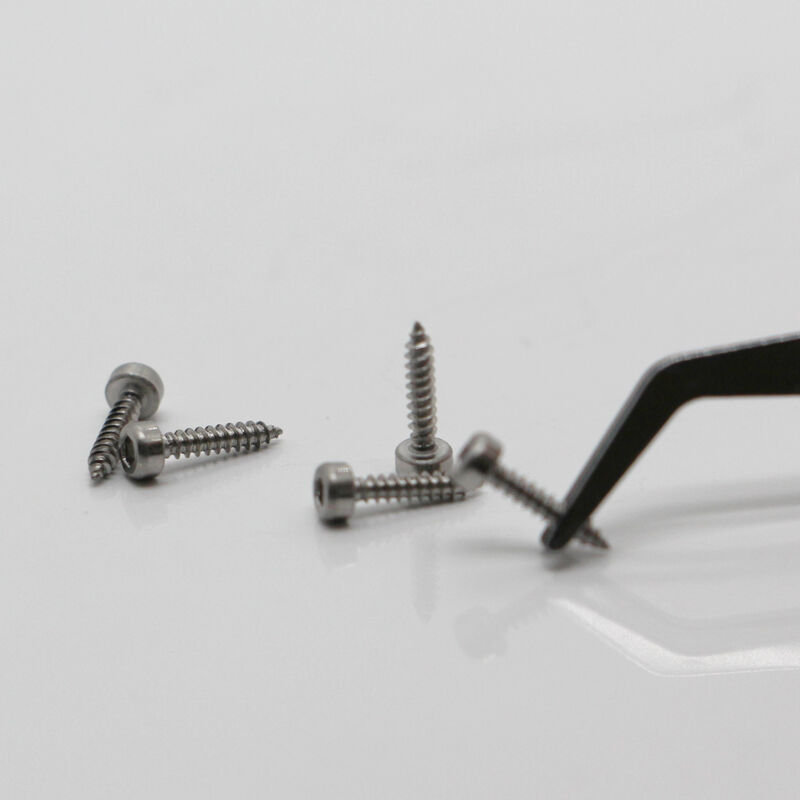

Parafuso autoatarraxante de corte com cabeça redonda de aço inoxidável

Esféricos em forma, parafusos micro esteticamente projetados para aplicações de precisão.

Nossa empresa é especializada em Pesquisa e Desenvolvimento e produção de parafusos micro de precisão M0.5-M3.0, com diâmetros de parafuso tão pequenos quanto M0.5 e comprimentos tão curtos quanto L0.85. Os materiais disponíveis incluem aço carbono, aço inoxidável e titânio. Os tipos de cabeça incluem estilos de cabeça K, P e C com tipos de rosca de máquina A e B.

Série de Produtos

Série de Parafusos Convencionais

Forjamento em aço inoxidável. Forjado em aço inoxidável primário, possui forte resistência ao atrito e durabilidade após inspeção rigorosa.

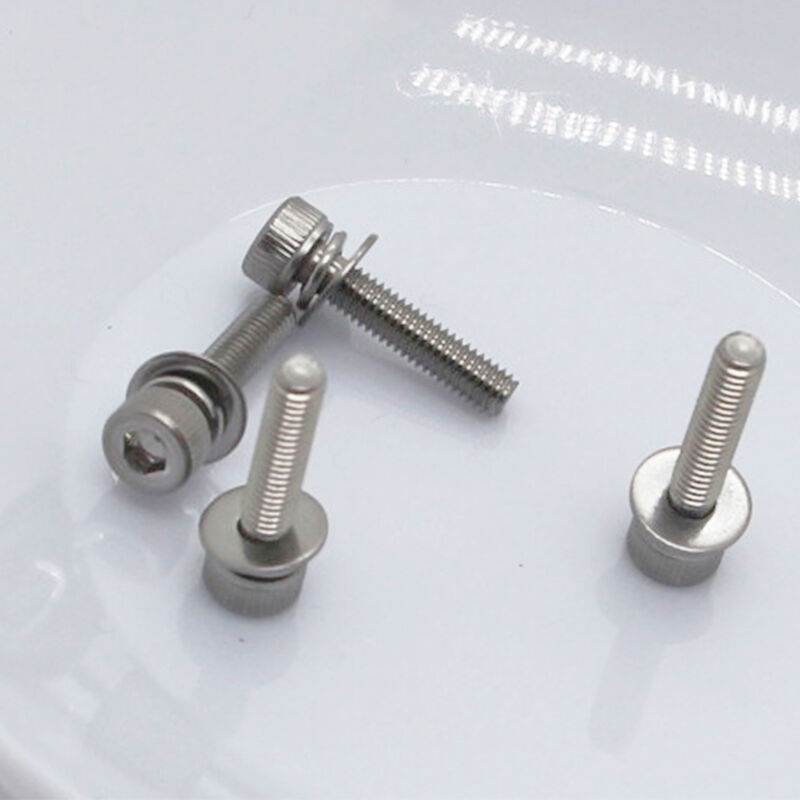

Série de Parafusos Sextavados

Material de aço inoxidável de alta qualidade selecionado, durável, resistente à corrosão e à ferrugem.

Porca de Rebite

- A parte de trás da placa deve estar completamente nivelada

- Pequeno e delicado, amplamente utilizado em produtos eletrônicos e elétricos de precisão ou equipamentos de precisão

- Alta resistência ao torque

- A série de especificações pode atender a uma variedade de requisitos de design

Produtos NC Estrangeiros

- A parte de trás da placa deve estar completamente nivelada

- Pequeno e delicado, amplamente utilizado em produtos eletrônicos e elétricos de precisão ou equipamentos de precisão

- Alta resistência ao torque

- A série de especificações pode atender a uma variedade de requisitos de design

Instalação de Fabricação

Atualmente, atendemos quase 100 clientes na indústria de displays de LED. Nosso escopo de negócios abrange vários setores, incluindo:

- Sistemas de computador e display LED

- Comunicações móveis

- Dispositivos vestíveis

- Indústrias de óculos/relógios/instrumentação

- Eletrônicos de precisão

Nos concentramos no desenvolvimento de parafusos não padronizados, com formatos personalizados, funcionais e específicos para componentes, componentes de hardware estampados, peças de usinagem mecânica e produtos relacionados a fixadores, como porcas, rebites e conectores. Nossas soluções atendem a diversas indústrias, incluindo máquinas, eletrônicos, medicina, aeroespacial e móveis.

Teste de Qualidade

Temos equipamentos de teste profissionais e uma equipe de teste dedicada, capazes de realizar testes abrangentes, incluindo:

- Medição de comprimento

- Coordenação de precisão

- Análise da composição química

- Teste de propriedades físicas

- Medição da espessura do filme de revestimento

Equipamento de Teste

Microscópio, máquina de montagem de amostras metalográficas, medição de concentricidade de diâmetro interno e externo, experimento de parafina, etc.

Métodos de Teste

Análise espectrográfica, teste de microdureza, rastreamento de contorno, teste de névoa salina, etc.

Embalagem e Entrega

Perguntas Frequentes

P: Em que tipos de parafusos e fixadores você é especializado?

R: Nos concentramos na fabricação de micro-parafusos de precisão (M0.5-M3.0) e fixadores relacionados, incluindo parafusos não padronizados, com formatos personalizados, parafusos funcionais/componentizados, porcas, rebites e peças de hardware estampadas/usinadas. Nossos produtos são amplamente utilizados em eletrônicos, wearables inteligentes, dispositivos médicos, aeroespacial e muito mais.

P: Você pode produzir parafusos ou fixadores personalizados para aplicações específicas?

R: Sim! Excelimos em P&D e produção de parafusos não padronizados, com formatos complexos e fixadores funcionais. Nossos engenheiros colaborarão com você para atender aos requisitos exclusivos de indústrias como dispositivos médicos, aeroespacial ou eletrônicos de precisão.

P: Qual é a sua quantidade mínima de pedido (MOQ)?

R: Oferecemos MOQs flexíveis, suportando prototipagem em pequenos lotes (para P&D) e produção em larga escala. Entre em contato conosco para soluções personalizadas.

P: Qual é o seu prazo de entrega típico para pedidos em massa?

R: Pedidos padrão levam de 25 a 35 dias (dependendo da complexidade). Mantemos linhas de produção eficientes e reservas de matéria-prima para atender a prazos urgentes.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!